Gaasaska birta ah ee birta ah dhamaystirka tayada iibka tooska ah ee warshadda

Guryaha Jirka

1. Waxaa jira ion koloriin deegaanka shaqada.

Iions Chloride waxaa laga helaa milixda, dhididka, biyaha badda, dabaysha, ciidda, iwm. Birta aan-dhalatada lahayn ayaa si degdeg ah u daxalaysa joogitaanka ion chloride marka loo eego birta fudud ee caadiga ah.

Sidaa daraadeed isticmaalka deegaanka birta aan la taaban karin ayaa leh shuruudo, iyo baahida loo qabo in marar badan la tirtiro, laga saaro boodhka, nadiifinta iyo qallajinta.(Tani waxay siinaysaa "isticmaalka aan habboonayn.")

Waxaa jira tusaale gudaha Maraykanka: shirkad ayaa adeegsatay weel geedeed si ay u qabato xal ka kooban ion chloride.Kunteenarkan ayaa la isticmaalayey in ka badan boqol sano, waxaana la qorsheeyay in la bedelo sagaashamaadkii.Sababtoo ah maaddada geedku ma ahayn mid casri ah oo ku filan, weelka waa daxalaystay oo daatay 16 maalmood ka dib beddelka birta aan fiicnayn.

2. Daawaynta xal la'aan.

Walxaha Alloy kuma milmin shaxanka, taasoo keentay in content alloy hoose ee qaab-dhismeedka matrix iyo iska caabin daxalka liidata.

3. Qalabka noocan oo kale ah oo aan lahayn titanium iyo niobium waxay leeyihiin dabeecad dabiici ah oo ku saabsan daxalka intergranular.

Ku darida titanium iyo niobium, oo ay weheliso daaweyn xasilloon, waxay yarayn kartaa daxalka intergranular.

Hawada ama dhexdhexaadinta daxalka kiimikada waxay iska caabin kartaa daxalka birta aluminiumka ah ee sare, birta aan lahayn waa dusha qurux badan iyo iska caabbinta daxalka wanaagsan, ma aha in la dhejiyo iyo daawaynta kale ee dusha sare, oo ay ciyaaraan sifooyinka dusha sare ee birta birta ah, loo isticmaalo dhinacyo badan oo ka mid ah nooca birta, sida caadiga ah loo yaqaan ahama.Anigoo ka wakiil ah waxqabadka 13 chromium steel, 18-8 chromium nikkel birta iyo birta kale ee alloy sare.

Laga soo bilaabo barta metallographic ee view, sababtoo ah ahama ka kooban chromium iyo dusha sare ee samaynta filim chromium aad u khafiif ah, filimku ka soocay ogsijiinta ee duulaanka birta ee iska caabinta daxalka.

Si loo joogteeyo iska caabbinta daxalka ee ku jira birta, birta waa in ay ka kooban tahay in ka badan 12% chromium.

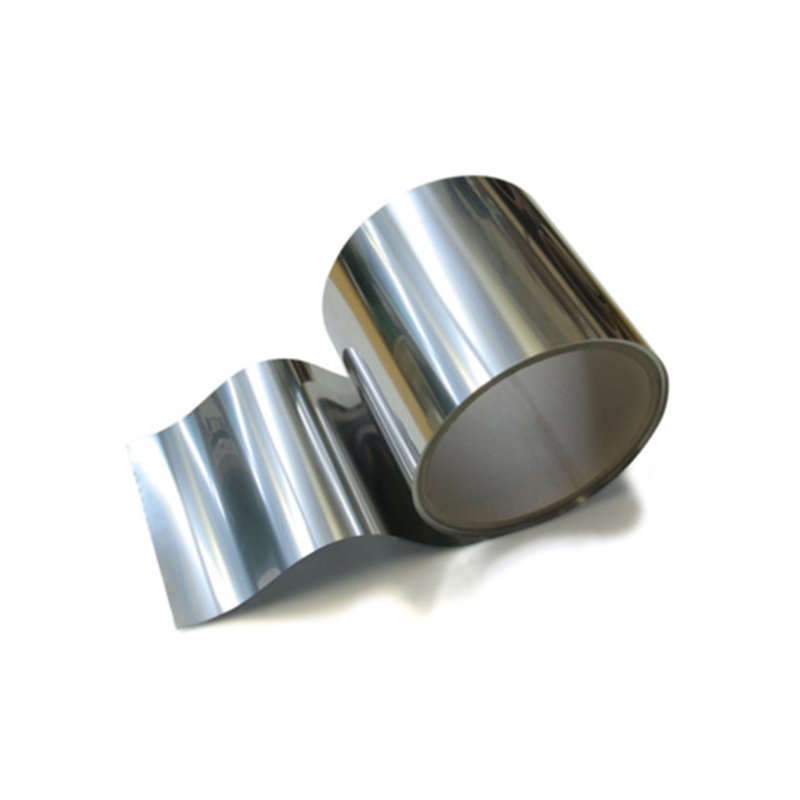

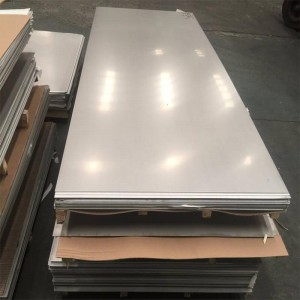

304Stainless steel Shim Plates waa bir caalami ah oo aan caadi ahayn, kaas oo si weyn loogu isticmaalo soo saarista qalabka iyo qaybaha u baahan sifooyin dhammaystiran oo wanaagsan (iska caabin daxalka iyo qaabaynta).

304 birta aan dahsoon waa sumad bir ah oo la soo saaray si waafaqsan heerarka ASTM ee Maraykanka.304 waxay u dhigantaa Shiinaha 0Cr19Ni9 (0Cr18Ni9) birta aan lahayn.304 ka kooban 19% chromium iyo 9% nikkel.

304 waa birta u adkeysata ee aan lahayn/kuleylka ugu isticmaalka badan.Loo isticmaalo qalabka wax soo saarka cuntada/qalabka kiimikada xiton/tamarta nukliyeerka, iwm.

304 waxay u dhigantaa sumadda Shiinaha 0Cr18Ni9,1Cr18Ni9Ti, kaarboonka ≤0:08%

304Lstainless steel Shim Plates waa nooc ka mid ah 304stainless steel Shim Plates ahama oo leh kaarboon hoose waxaana loo isticmaalaa codsiyada alxanka.Waxa ku jira kaarboonka hoose waxa ay yaraynaysaa roobabka karbides ee aagga kulaylku saameeyay ee u dhow alxanka, taas oo u horseedi karta daxalka intergranular (nabaad guurka alxanka) ee birta aan fiicnayn ee meelaha qaarkood.

Halbeegyada

| T | qallafsanaan | qallafsanaan | Xaaladda daawaynta kulaylka adkeynaysa roobabka | dhaqdhaqaajin% | ||||||

| qallafsanaan | qallafsanaan | Awood-soo-saarka N/mm | Xoog xajin N/mm | dheerayn% | Daaweynta kulaylka | adkaantaHV | Awood-soo-saarka N/mm | Xoog xajin N/mm | ||

| 301-CSP | 1/2H | 340± 30 | ≥510 | ≥930 | ≥10 | - | - | - | - | 2.3 |

| 3/4H | 400± 30 | ≥745 | ≥1130 | ≥5 | - | - | - | - | 2.3 | |

| H | 460± 30 | ≥1030 | ≥1320 | - | - | - | - | - | 2.3 | |

| EH | 510± 20 | ≥1275 | ≥1570 | - | - | - | - | - | 2.3 | |

| SEH | ≥530 | ≥1450 | ≥1740 | - | - | - | - | - | 2.3 | |

| 304-CSP | 1/2H | 280± 30 | ≥470 | ≥780 | ≥6 | - | - | - | - | 2.3 |

| 3/4H | 340± 30 | ≥665 | ≥930 | ≥3 | - | - | - | - | 2.3 | |

| H | ≥370 | ≥880 | ≥1130 | - | - | - | - | - | 2.3 | |

| 631-CSP | 0 | ≤200 | - | ≤1030 | ≥20 | TH1050RH950 | ≥345≥392 | ≥960≥1030 | ≥1140≥1230 | 2.3 |

| 1/2H | 375±25 | - | ≥1080 | ≥5 | CH | ≥380 | ≥880 | ≥1230 | 2.3 | |

| 3/4H | 425±25 | - | ≥1180 | CH | ≥450 | ≥1080 | ≥1420 | 2.3 | ||

| H | ≥450 | - | ≥1420 | CH | ≥530 | ≥1320 | ≥1720 | 2.3 | ||